How to Implement a Consistent Recipe Management Process

Learn how to implement a consistent recipe management process with ERP systems, ensuring quality, compliance, and efficiency in food and beverage operations.

In the fast-paced, highly competitive food and beverage industry, delivering consistent, high-quality products is non-negotiable. Whether you’re running a restaurant, managing a food manufacturing plant, or operating a retail food business, a consistent recipe management process is the backbone of operational success. It ensures that every dish or product meets customer expectations, complies with regulatory standards, and maintains profitability. With the rise of digital solutions like Food and Beverage Enterprise Resource Planning (ERP) systems, businesses can streamline recipe management, reduce errors, and boost efficiency.

This comprehensive guide explores how to implement a consistent recipe management process, leveraging advanced tools like ERP systems to optimize operations. From recipe creation to compliance, cost control, and scalability, we’ll cover every aspect of building a robust system tailored to your business needs. Along the way, we’ll include practical tips, key features to look for in software, and real-world applications to help you succeed.

What is Recipe Management?

Recipe management is the systematic process of creating, organizing, storing, and managing recipes within a food production or culinary environment. It involves documenting critical details such as ingredients, quantities, preparation instructions, nutritional data, allergens, and costs. Effective recipe management ensures consistency in product quality, compliance with food safety regulations, and operational efficiency.

Key Components of Recipe Management

- Recipe Creation and Standardization: Developing recipes with precise measurements and instructions to ensure replicable results.

- Ingredient Management: Tracking inventory, procurement, and usage to minimize waste and ensure availability.

- Cost Analysis: Calculating ingredient, labor, and overhead costs to determine profitability.

- Compliance and Allergen Management: Ensuring recipes meet regulatory standards and clearly identify allergens.

- Scaling and Version Control: Adjusting recipes for different batch sizes and tracking changes over time.

- Production Planning: Scheduling production based on demand and resource availability.

- Quality Control: Monitoring product quality to meet safety and taste standards.

Why is Recipe Management Critical?

Consistency in food production directly impacts customer satisfaction, brand reputation, and revenue. Studies show that over 90% of dissatisfied customers won’t return to a food establishment, and they’re likely to share their negative experiences with 9–15 people. A single inconsistent dish can trigger a domino effect, harming your business. Here’s why recipe management matters:

- Customer Loyalty: Consistent quality keeps customers coming back.

- Cost Control: Accurate costing prevents profit loss due to fluctuating ingredient prices.

- Regulatory Compliance: Proper documentation ensures adherence to food safety laws.

- Operational Efficiency: Streamlined processes reduce errors and save time.

- Scalability: A robust system supports business growth without compromising quality.

Challenges in Traditional Recipe Management

Historically, recipe management has been a manual, error-prone process. Common challenges include:

- Manual Data Entry: Relying on paper invoices or spreadsheets increases the risk of errors.

- Time Constraints: Busy restaurant staff often lack time to update recipes or calculate costs.

- Complex Calculations: Scaling recipes or factoring in ingredient price changes is tedious without automation.

- Lost Documentation: Paper records are easily misplaced, disrupting operations.

- Inconsistent Quality: Lack of standardization leads to variations in taste or presentation.

These challenges highlight the need for a digital solution to modernize recipe management.

Leveraging Food and Beverage ERP Systems

Food and Beverage ERP systems are comprehensive software platforms designed to integrate and optimize business processes, including recipe management. By centralizing data and automating tasks, ERP systems address the shortcomings of manual methods. Here’s how they revolutionize recipe management:

Centralized Recipe Database

A centralized database stores all recipes in one accessible location, acting as a single source of truth. This eliminates confusion from multiple recipe versions and ensures that chefs, managers, and production staff work with the latest data.

Benefits:

- Easy access from any device, including mobile.

- Real-time updates to recipes and ingredient prices.

- Collaboration across teams and locations.

Version Control

Version control tracks changes to recipes, documenting who made revisions and why. This ensures accountability and allows businesses to revert to previous versions if needed.

Example:

A chef modifies a pasta sauce recipe to use a cheaper ingredient. Version control logs the change, enabling the team to compare the new version’s cost and quality against the original.

Costing and Pricing

ERP systems integrate with supplier data to provide real-time ingredient price updates, enabling accurate cost calculations. Businesses can analyze recipe profitability and adjust pricing strategies dynamically.

Table: Sample Recipe Cost Breakdown

| Ingredient | Quantity | Unit Cost | Total Cost |

|---|---|---|---|

| Flour | 2 kg | $1.50/kg | $3.00 |

| Olive Oil | 500 mL | $5.00/L | $2.50 |

| Tomatoes | 1 kg | $2.00/kg | $2.00 |

| Labor (2 hrs) | – | $15/hr | $30.00 |

| Total | – | – | $37.50 |

Note: This table illustrates how ERP systems break down costs for a single recipe, helping managers identify opportunities to reduce expenses.

Supplier Integration

ERP systems connect with suppliers to update ingredient prices and availability automatically. This streamlines procurement and ensures recipes remain cost-effective.

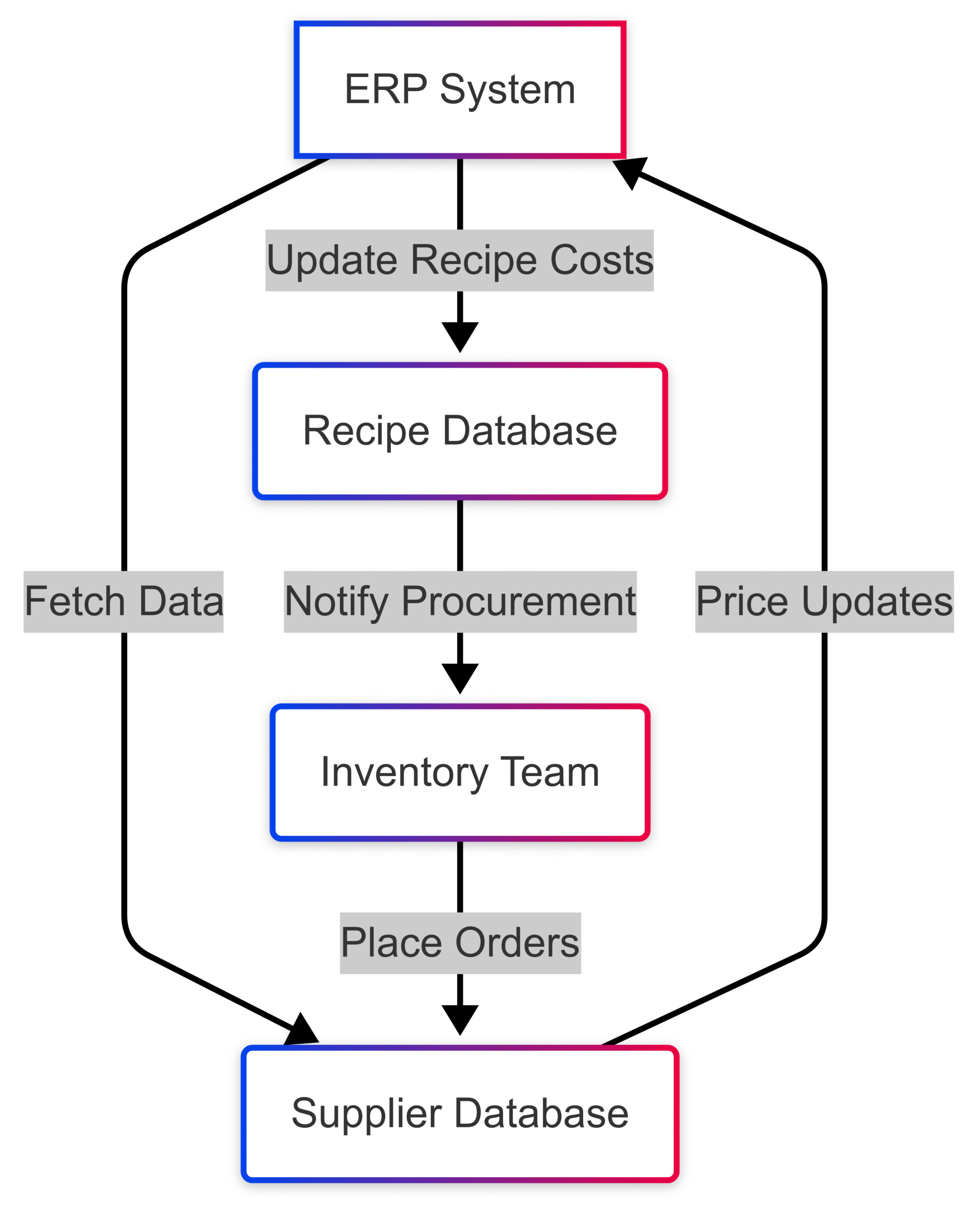

Chart: Supplier Integration Workflow

This chart shows how ERP system automates price updates and procurement, ensuring accurate recipe costing.

Compliance and Allergen Management

ERP systems ensure compliance with food safety regulations by generating accurate labels and allergen warnings. Automated checks highlight potential issues, such as undeclared allergens, reducing legal risks.

Example:

A recipe containing peanuts triggers an allergen alert, prompting the system to add a warning to the menu and packaging.

Batch Tracking and Traceability

Batch tracking ingredients from source to final product, ERP systems enhance traceability. This is critical for recalls, ensuring businesses can quickly identify affected batches and act swiftly.

Example:

If a supplier recalls contaminated spinach, the ERP system traces which batches used the ingredient, minimizing recall scope and protecting customers.

Production Planning and Scheduling

ERP systems optimize production by aligning recipes with demand forecasts and resource availability. This ensures efficient use of ingredients, labor, and equipment.

Table: Production Schedule Example

| Recipe | Batch Size | Production Date | Resources Needed |

|---|---|---|---|

| Tomato Soup | 100 L | Monday | 2 chefs, 1 pot, 4 hrs |

| Garlic Bread | 200 units | Tuesday | 1 baker, oven, 2 hrs |

| Caesar Salad | 50 servings | Wednesday | 1 prep cook, 1 hr |

This schedule ensures resources are allocated efficiently, preventing bottlenecks.

Quality Control

ERP systems enforce quality standards through automated checks and testing protocols. Real-time monitoring detects deviations, ensuring consistent product quality.

Mobile Accessibility

Mobile access allows staff to view and update recipes on the go, enhancing flexibility. Chefs can adjust recipes in real-time, and managers can monitor production remotely.

Analytics and Reporting

Advanced analytics provide insights into recipe performance, cost trends, and production efficiency. Customizable reports help businesses make data-driven decisions.

Example Report: Recipe Profitability

- Recipe: Margherita Pizza

- Cost per Serving: $3.50

- Selling Price: $12.00

- Profit Margin: 70.83%

- Sales Volume: 500 units/month

- Total Profit: $4,250/month

This report helps identify high-performing recipes and areas for cost optimization.

Key Features to Look for in Recipe Management Software

When selecting a recipe management system or ERP, prioritize these features:

- Recipe Creation and Customization: Supports detailed recipe documentation and adjustments.

- Cost Analysis: Provides real-time cost calculations and profitability insights.

- Scaling Capabilities: Accurately adjusts recipes for different batch sizes.

- Version Control: Tracks recipe changes with a clear revision history.

- Allergen and Nutritional Tracking: Highlights allergens and generates nutritional data.

- Integration: Connects with inventory, POS, and supplier systems.

- Mobile Access: Enables remote recipe management.

- Analytics: Offers robust reporting for performance tracking.

Comparing Popular Recipe Management Software

Here’s a comparison of popular recipe management tools to help you choose the best fit:

Table: Recipe Management Software Comparison

| Software | Key Features | Pricing | Pros | Cons |

|---|---|---|---|---|

| Paprika | Recipe import, meal planning, mobile app | $4.99 (one-time, per platform) | User-friendly, affordable | Limited business features |

| BigOven | Cloud sync, nutritional data, sharing | Free; Pro: $2.99/month | Modern interface, iPhone app | Public sharing of recipes |

| RecipeSage | URL import, open-source, free | Donation-based | Cost-effective, customizable | Limited support |

| Deskera ERP | Recipe management, costing, compliance | Contact for quote | Comprehensive, scalable | Higher cost for small businesses |

| xtraCHEF | Invoice automation, recipe costing | Contact for quote | Accurate costing, integration | Complex for small operations |

Recommendation: For home cooks or small businesses, Paprika or RecipeSage offer affordable, user-friendly solutions. For larger operations, Deskera or xtraCHEF provide robust ERP features tailored to the food industry.

8 Tips for Effective Recipe Management

To maximize the benefits of your recipe management system, follow these tips:

- Train Staff Thoroughly: Ensure all users understand the software’s features and updates.

- Use Automation for Calculations: Rely on the system for scaling and cost computations to reduce errors.

- Mass Upload Recipes: Import existing recipes in bulk to save time and minimize mistakes.

- Verify Base Recipes: Double-check original recipes to ensure accurate scaling and costing.

- Include Substitute Ingredients: Log alternatives to maintain production during shortages.

- Leverage Allergen Features: Use automated allergen tracking to enhance safety.

- Communicate Changes: Notify staff of recipe updates to ensure consistency.

- Review Costs Regularly: Monitor ingredient prices and adjust recipes to maintain profitability.

Case Study: Implementing Deskera ERP in a Mid-Sized Restaurant Chain

A mid-sized restaurant chain with five locations struggled with inconsistent dishes and rising costs due to manual recipe management. By implementing Deskera’s Food and Beverage ERP, they achieved:

- Centralized Recipes: All locations accessed standardized recipes, reducing variations.

- Cost Savings: Real-time cost analysis identified a 15% reduction in ingredient expenses by switching to alternative suppliers.

- Compliance: Automated allergen tracking ensured compliance with local regulations.

- Efficiency: Production planning reduced prep time by 20%, allowing staff to focus on customer service.

The chain reported a 25% increase in customer satisfaction and a 10% boost in profit margins within six months.

Conclusion

Implementing a consistent recipe management process is essential for food and beverage businesses aiming to deliver high-quality products, ensure compliance, and maintain profitability. By leveraging Food and Beverage ERP systems like Deskera, businesses can centralize recipes, automate costing, streamline production, and enhance quality control. With features like mobile accessibility, version control, and advanced analytics, these systems empower teams to work smarter, not harder.

Whether you’re a small restaurant or a large manufacturer, investing in a robust recipe management system will transform your operations. Start by assessing your needs, comparing software options, and training your team to maximize the benefits. With the right tools, you’ll ensure every dish delights customers and drives your business forward.

Call to Action: Ready to streamline your recipe management? Explore Deskera’s Food and Beverage ERP with a free demo at Deskera.com and take control of your operations today.

Please share these How to Implement a Consistent Recipe Management Process with your friends and do a comment below about your feedback.

We will meet you on next article.

Until you can read, How To Take Food Photos That Look Truly Delicious