Food Science Tips for Consistent Food Quality

Discover expert food science tips to ensure consistent food quality across batches. Learn to standardize recipes, control processes, and leverage technology for success.

In the fast-paced and highly competitive food and beverage (F&B) industry, delivering consistent food quality across every batch or dish is not just a goal—it’s a necessity. Consistency builds customer trust, strengthens brand reputation, and drives repeat business, whether you’re operating a restaurant, food manufacturing facility, or a small-scale culinary enterprise. Variations in taste, texture, or appearance can erode customer loyalty and harm your brand’s credibility. Achieving uniformity requires a strategic blend of science, operational precision, and innovative technology. This article explores actionable food science tips to ensure consistent food quality, drawing on expert insights and practical strategies to help F&B businesses thrive.

Why Food Consistency Matters

Consistency in food quality refers to delivering the same taste, texture, aroma, appearance, and portion size with every product or dish. It’s the assurance that a customer’s favorite dish will taste just as good on their tenth visit as it did on their first. Here’s why consistency is critical:

- Customer Satisfaction and Loyalty: Customers expect the same high-quality experience every time they engage with your brand. Inconsistent quality can lead to dissatisfaction, negative reviews, and lost business. Consistent quality, however, fosters trust and encourages repeat purchases.

- Brand Reputation and Recognition: A consistent product creates a recognizable brand identity. Iconic brands like McDonald’s or The Capital Grille thrive because customers know exactly what to expect, regardless of location. Consistency reinforces your brand’s promise and sets you apart in a crowded market.

- Operational Efficiency: Standardized processes reduce errors, minimize waste, and streamline production. This leads to cost savings and improved profitability, especially for small and medium-sized enterprises (SMEs) with tight margins.

- Regulatory Compliance and Safety: Consistency ensures adherence to food safety standards, reducing the risk of foodborne illnesses and regulatory penalties. Uniform processes help maintain high hygiene and quality standards.

- Market Expansion: Consistent quality builds trust with distributors, retailers, and investors, enabling businesses to scale and explore new markets with confidence.

Key Strategies for Consistent Food Quality

To achieve and maintain food consistency, F&B businesses must adopt a systematic approach that integrates science, technology, and human expertise. Below are six proven strategies, supported by expert insights and practical examples.

1. Standardize Recipes for Precision

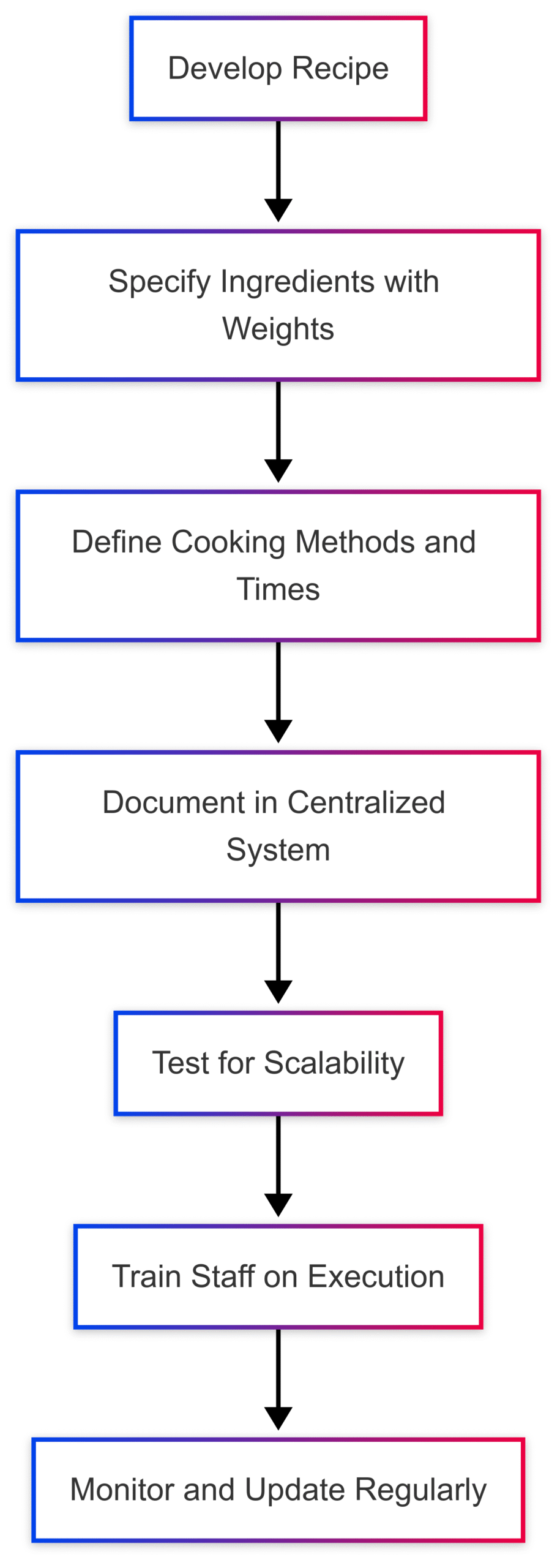

Standardized recipes are the cornerstone of consistent food quality. A standardized recipe acts as a blueprint, ensuring every batch or dish is produced with precision. Here’s how to implement this strategy effectively:

- Use Weight-Based Measurements: Volume measurements (e.g., cups) can vary due to factors like ingredient density or environmental conditions. Weight-based measurements (e.g., grams) offer greater accuracy. For example, a bakery producing sourdough bread should specify flour in grams to account for variations in humidity.

- Define Clear Instructions: Include detailed steps for preparation, cooking methods, temperatures, and times. For instance, a recipe for homemade pasta should specify kneading time and resting periods to ensure consistent texture.

- Document and Update Regularly: Maintain a centralized recipe database and update it to reflect ingredient changes or process improvements. Digital recipe management software can enhance accuracy and accessibility.

- Ensure Scalability: Recipes should be adaptable for larger production volumes without compromising quality. Test recipes at different scales to confirm consistency.

Example: A mid-sized bakery struggling with inconsistent sourdough loaves implemented a standardized recipe checklist using weight-based measurements and precise fermentation times. This reduced variability by 25% and improved customer satisfaction.

Chart: Recipe Standardization Process

2. Control Processes with Precision

Process control is critical in food manufacturing and restaurant operations. Variations in temperature, pH, or cooking times can alter the final product. Here’s how to maintain strict process control:

- Implement Standard Operating Procedures (SOPs): SOPs outline every step of the production process, from mixing to packaging. For example, a sauce manufacturer should specify mixing speeds and cooking temperatures to ensure uniform flavor.

- Monitor Critical Parameters: Use sensors to track temperature, humidity, and pH in real-time. IoT-enabled devices can alert operators to deviations, preventing quality issues.

- Adopt HACCP Plans: A Hazard Analysis and Critical Control Points (HACCP) plan identifies potential risks and establishes control measures. For instance, a meat processing plant might monitor cooking temperatures to ensure pathogen elimination.

- Calibrate Equipment Regularly: Uncalibrated equipment, such as ovens or fryers, can lead to inconsistent results. Regular maintenance ensures optimal performance.

Case Study: PureFlavors, an organic juice manufacturer, faced flavor inconsistencies due to variable fruit quality. By installing IoT sensors to monitor pH and temperature, they reduced quality issues by 30% and maintained uniform taste across batches.

Table: Key Process Control Parameters

| Parameter | Monitoring Tool | Frequency | Impact on Quality |

|---|---|---|---|

| Temperature | IoT Sensors | Real-Time | Ensures consistent cooking |

| pH Level | pH Meters | Per Batch | Affects flavor and safety |

| Mixing Speed | Automated Mixers | Per Batch | Uniform texture |

| Cooking Time | Timers/Alarms | Per Batch | Consistent doneness |

3. Train Staff for Consistency

Well-trained staff are the backbone of consistent food quality. Employees must understand recipes, processes, and the importance of adherence. Here’s how to build a skilled team:

- Conduct Regular Training: Offer hands-on and theoretical training sessions. For example, a restaurant can use video tutorials to demonstrate proper frying techniques for consistent texture.

- Use Checklists: Provide checklists for critical tasks, such as ingredient preparation or plating. Digital platforms like Manifestly Checklists ensure real-time updates and compliance.

- Foster a Culture of Accountability: Encourage staff to report deviations and suggest improvements. Peer reviews and supervisor feedback can enhance attention to detail.

- Address Turnover: High staff turnover can disrupt consistency. Standardized training materials and checklists help new hires quickly align with established protocols.

Example: A high-end restaurant implemented a checklist-based training program for its pasta dishes, reducing preparation errors by 15% and ensuring uniform quality across shifts.

4. Source High-Quality Ingredients

The quality of raw materials directly impacts product consistency. Variations in ingredient quality can lead to noticeable differences in the final product. Here’s how to ensure ingredient reliability:

- Build Strong Supplier Relationships: Partner with suppliers who provide consistent, high-quality ingredients. Request Certificates of Analysis (COAs) to verify specifications.

- Conduct Routine Quality Checks: Inspect ingredients for freshness, flavor, and compliance with standards before use. For example, a bakery should test flour for protein content to ensure consistent dough performance.

- Adapt to Variability: Develop guidelines for adjusting recipes when ingredient quality varies. For instance, a chef might adjust seasoning for seasonal produce to maintain flavor profiles.

- Centralize Purchasing: For multi-location businesses, centralized purchasing ensures all sites receive uniform ingredients, reducing variability.

Case Study: A fresh produce brand partnered with SmartDev to implement a cloud-based system for tracking ingredient quality. This reduced manual errors and ensured consistent raw materials across production.

5. Analyze Feedback for Continuous Improvement

Feedback from customers and internal quality control provides valuable insights into consistency issues. Here’s how to leverage feedback effectively:

- Collect Customer Feedback: Use surveys, online reviews, and social media to gauge customer satisfaction. For example, a change in texture reported by customers might indicate a process deviation.

- Conduct Sensory Evaluations: Regular taste panels and sensory tests can identify variations in flavor, texture, or appearance. Train staff to perform these evaluations consistently.

- Implement Batch Tracking: Traceability systems allow businesses to pinpoint the source of inconsistencies. For instance, a manufacturer can trace a batch with off-flavors to a specific supplier.

- Act on Insights: Use feedback to refine recipes, processes, and training. Data analytics can identify trends and guide improvements.

Example: A restaurant chain used customer feedback to identify inconsistent portion sizes. By implementing a batch tracking system and adjusting portioning guidelines, they improved customer satisfaction by 20%.

Chart: Customer Feedback Impact on Quality

6. Innovate Continuously with Technology

The F&B industry is dynamic, and staying ahead requires embracing innovation. Technology can enhance consistency and streamline operations. Here’s how to innovate:

- Adopt Automation: Automated systems, such as mixing or packaging equipment, reduce human error and ensure uniformity. For example, an automated fryer oil management system maintains consistent frying results.

- Leverage IoT and AI: IoT sensors monitor production conditions, while AI-powered visual inspection systems detect defects in real-time. These tools enhance precision and scalability.

- Use Data Analytics: Analytics platforms identify trends and optimize processes. For instance, predictive maintenance tools can prevent equipment failures that disrupt consistency.

- Invest in R&D: Experiment with new ingredients, techniques, or equipment to improve quality. Collaborate with food scientists and suppliers to stay updated on industry trends.

Case Study: SmartDev’s client, a fresh produce brand, implemented a cloud-based data processing system to automate quality checks. This reduced manual errors by 40% and ensured consistent product quality.

Addressing Challenges in Food Consistency

Despite best efforts, challenges like ingredient variability, environmental factors, and scaling issues can disrupt consistency. Here’s how to tackle them:

- Ingredient Variability: Use supply chain management software to track supplier performance and ingredient quality. Adjust recipes as needed to compensate for variations.

- Environmental Factors: Install IoT sensors to monitor temperature, humidity, and airflow. Automated systems can adjust equipment settings to maintain stable conditions.

- Scaling Challenges: Implement scalable production management systems to adjust recipes and processes for larger volumes. Predictive maintenance ensures equipment reliability during scale-up.

Tools and Technologies for Consistency

Several tools can support consistent food quality:

- Manifestly Checklists: Digital checklists streamline recipe execution and training, ensuring compliance and real-time updates.

- Restaurant Technologies: Automated oil management and kitchen equipment solutions maintain consistent cooking results.

- SmartDev Solutions: IoT systems, data analytics, and supply chain management tools enhance quality control and scalability.

- Supy: Inventory management software optimizes procurement and reduces waste, ensuring consistent ingredient quality.

Table: Technology Solutions for Food Consistency

| Tool | Function | Benefits | Price (Estimated) |

|---|---|---|---|

| Manifestly Checklists | Digital recipe and process checklists | Streamlines operations, reduces errors | $5-$15/user/month |

| Restaurant Technologies | Automated oil management, equipment maintenance | Consistent cooking, reduced downtime | Contact for custom pricing |

| SmartDev IoT Systems | Real-time monitoring of production conditions | Prevents quality issues, scalable | Custom pricing |

| Supy | Inventory and procurement management | Ensures ingredient consistency | Contact for pricing |

Success Stories in Food Consistency

- McDonald’s: The global fast-food giant maintains consistency through standardized recipes, rigorous training at Hamburger University, and advanced technology like digital kiosks. This ensures a Big Mac tastes the same worldwide.

- The Capital Grille: This upscale dining chain uses regional managers to conduct quality audits and comprehensive staff training to deliver consistent high-end dining experiences across locations.

- PureFlavors: By adopting IoT-driven quality control, this organic juice brand reduced quality issues by 30%, enhancing customer trust and loyalty.

Conclusion

Maintaining consistent food quality is a multifaceted challenge that requires precision, training, and innovation. By standardizing recipes, controlling processes, training staff, sourcing quality ingredients, analyzing feedback, and embracing technology, F&B businesses can deliver the same exceptional experience with every batch or dish. Tools like Manifestly Checklists, Restaurant Technologies, and SmartDev solutions empower businesses to streamline operations and build a reputation for reliability.

Consistency is not just about meeting customer expectations—it’s about exceeding them, fostering loyalty, and driving long-term success. Whether you’re a restaurant owner, food manufacturer, or SME, these food science tips provide a roadmap to achieve uniformity and elevate your brand. Take the first step by integrating technology and standardized processes into your operations, and watch your business thrive in the competitive F&B landscape.

Please share these Food Science Tips for Consistent Food Quality with your friends and do a comment below about your feedback.

We will meet you on next article.

Until you can read, How to Implement a Consistent Recipe Management Process